He installed the Andon Cord—a physical rope above every station.

If a worker saw a defect, they were obligated to pull it.

But when they brought this to the US in 1984, there was a problem:

The Americans were too terrified to pull it.

Decades of US car culture taught workers that stopping the line equals getting fired.

If a worker saw a defect, they were obligated to pull it.

But when they brought this to the US in 1984, there was a problem:

The Americans were too terrified to pull it.

Decades of US car culture taught workers that stopping the line equals getting fired.

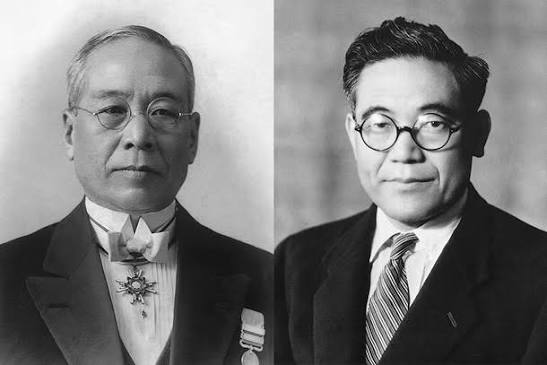

Then, CEO Tetsuro Toyoda saw a man struggling. “Pull it,” he urged.

The worker refused: “I can fix it, sir.”

Toyoda didn't argue.

He grabbed the man’s hand and pulled the cord with him.

Silence. Alarms flashed. $15,000/minute burning.

Toyoda bowed to the worker:

“Forgive me. I failed to show you that only YOU can make the best cars.”

The worker refused: “I can fix it, sir.”

Toyoda didn't argue.

He grabbed the man’s hand and pulled the cord with him.

Silence. Alarms flashed. $15,000/minute burning.

Toyoda bowed to the worker:

“Forgive me. I failed to show you that only YOU can make the best cars.”

You didn't just fix a car; you fixed the system.

While Detroit spent 25% of its budget on "rework,"

Toyota’s defect rate hit near zero.

They weren't just faster; they were better and cheaper.

But the Andon Cord didn't only exist in factories.

Decades later, Jeff Bezos created the “customer service andon cord.”

While Detroit spent 25% of its budget on "rework,"

Toyota’s defect rate hit near zero.

They weren't just faster; they were better and cheaper.

But the Andon Cord didn't only exist in factories.

Decades later, Jeff Bezos created the “customer service andon cord.”

Tesla uses a Digital Andon Cord.

If sensors detect a 1mm deviation, the robots halt.

As Musk says: “You need a constant feedback loop of how you could be doing it better.”

But copying the cord doesn't guarantee success.

If sensors detect a 1mm deviation, the robots halt.

As Musk says: “You need a constant feedback loop of how you could be doing it better.”

But copying the cord doesn't guarantee success.

•Toyota: Became the #1 automaker globally.

•Amazon: Owns nearly 40% of US e-commerce.

•Tesla: Achieved the highest margins in the industry.

They all realized the same truth: To go fast, you must be willing to stop.

•Amazon: Owns nearly 40% of US e-commerce.

•Tesla: Achieved the highest margins in the industry.

They all realized the same truth: To go fast, you must be willing to stop.

جاري تحميل الاقتراحات...